Description

The goal was to retrofit a conventional D-Cell operated Maglite flash light to use the readily available and salvageable 18650 series rechargeable batteries. These batteries can be recovered from laptop battery packs that seem to be “dead” and generally have only one or two bad cells that also can often be recovered as well.

Introduction

The Maglite host body accepts two D-Cell batteries which are a bit shorter in length than an 18650 cell, unfortunately in my attempt to rid my home of non-rechargeable batteries I can not find a D-Cell battery for an image comparison. In order to accomplish this mod it would be necessary to accommodate the extra length from using two 18650 batteries. The 18650 cells are much slimmer than a D-Cell while packing several times the energy density and require a method of holding them in place to ensure proper electrical contact.

Finished Project

- Stock looking Maglight.

- Maglite with modded 18650 battery holder.

Bending the Spring

Fortunately and for mostly unexplainable reasons Maglite have decided to use a spring that is quite long and have similarly increased the length of the host body. I realized that by turning the spring around and bending the first turn of the base of the spring inward and upward slightly that it would be the perfect length to make contact with the 18650 cells while not pressing so hard as to cause damage.

Having swapped the old-world incandescent bulb for a more modern voltage regulated LED module quite some time ago there was no longer any need to carry an extra as the LED will likely out-live the other components like the switch.

The long side of the spring actually makes it stick out a bit when flipped around however once pressure is placed on the spring by making contact with the 1865 cells the spring sits flush inside the inner ring of the end cap. The decision was made to not trim or modify the long side of the spring to retain the original compatibility with D-Cell batteries.

Battery Holder

The 18650 battery cells being much slimmer than the original D-Cell batteries needed a custom holder for use in the Maglite. Owners of 3D printers will immediately see a way to improve upon my fabrication method of cardboard and super glue. This project is all about recycling and where others saw the box my beer came in I happened to see a project in the making.

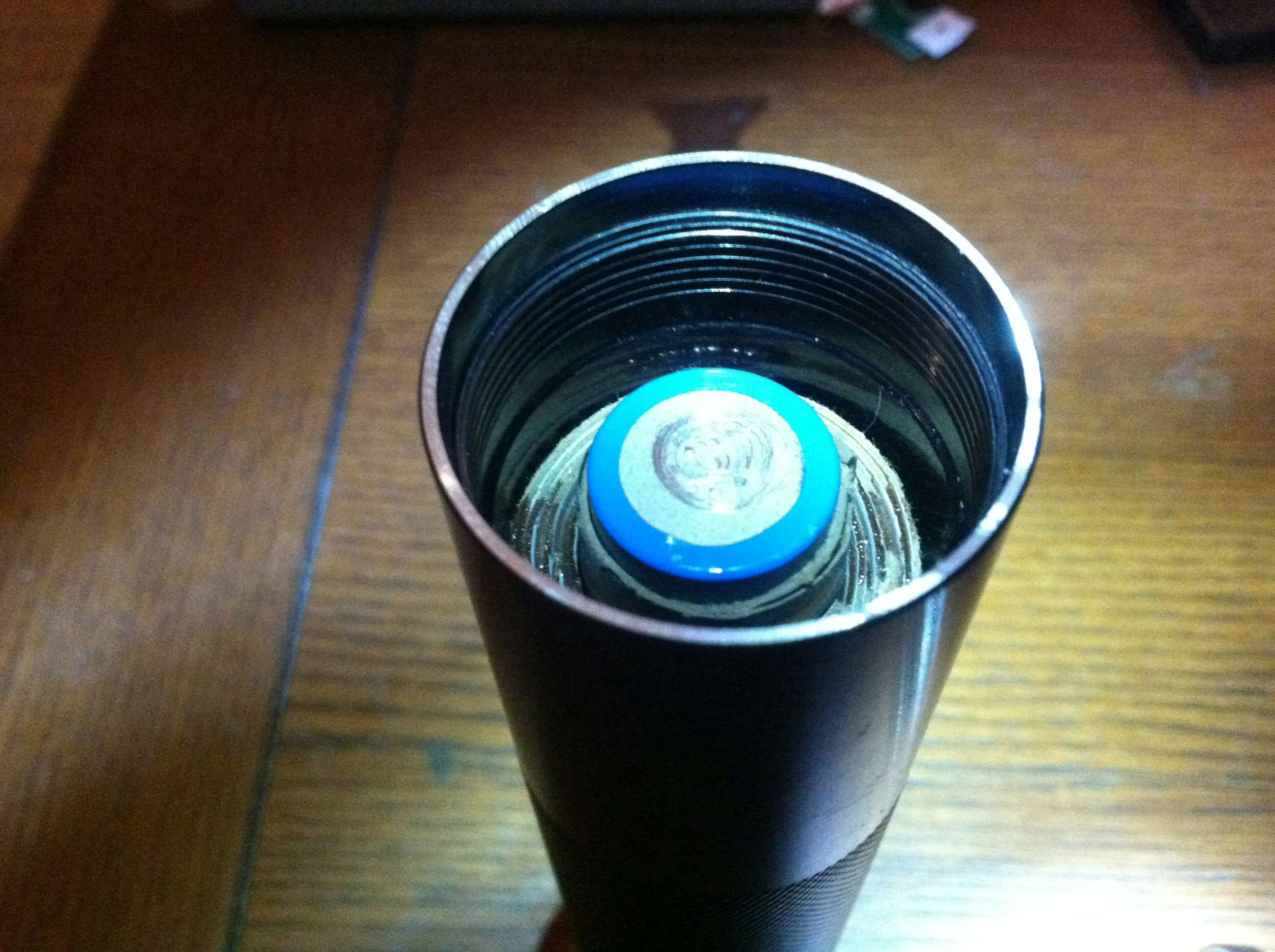

Construction started with a single piece of heavy non-corrugated cardboard approximately 4.75” x 8” rolled into a tube around some spare 16850 cells for size reference. The fit should be snug but not compressing such that the cells come out with a slight push. Lastly two longer strips of cardboard approximately 1.25” x 20” rolled around the first tube near the top and the bottom. The latter should be checked for fitting into the host body and trimmed as necessary depending on the thickness of the cardboard being used.

Anyone who has salvaged just about any type of rechargeable battery will have noticed that these cells generally do not have the small hump on the positive side like a conventional AA or D-Cell battery. For this reason it was necessary to either solder tabs on the batteries or use bits of metal to create the contact needed. A thin piece is added between the two cells and a more D-Cell style hump one for the top. Previously having soldered small humps on to rechargeable cells I have found that over time the solder tarnishes and lead to degraded electrical contact and requires constant cleaning. The aluminium foil looks a lot less professional by comparison however it won’t tarnish like the solder and by not using solder I keep this project to a list of common kitchen items making this type of project more accessible to everyone.

Finally the batteries inserted into the holder and the holder then inside the flash light ready for the end cap. The 18650 cells are so light in comparison to the original D-Cell batteries that the flash light feels as if it has no batteries at all making it easier and less tiresome to hold for long periods of time. The 18650 cells have several times the life-span of the D-Cell batteries and while I do not have any exact figures I can say that I left it on once overnight and then used it for several months afterwards and the light was as bright as ever. The wide range of input on the bulb I chose means the light will continue to function well past the normal useful voltages of the cells.